This is an extract from a mini toolkit ’10+ Techniques to adopt from the lean movement ‘ (article +E-Templates) that can be source from this link.

The lean movement, which started in Japan during the rebuild after the Second World War, had an American influence, Edwards Deming.2 The lean methods developed by the Japanese multinationals have now spread far and wide into all sectors. There have been many institutes and consultancy methodologies that make up the lean movement as we see it today.

1. Lean is about eliminating the eight wastes

In lean methodology, there are eight types of waste. These wastes are seen within the whole organisation and within the accounting function. I have outlined the eight wastes below in Exhibit 1

Exhibit 1: The Eight Wastes that Need Tackling

| Over-production: Building batches of products larger than the customers’ immediate need. Printing marketing brochures in advance. |

| Waiting: Production operators waiting because a machine has gone down, or a component is not available. Operators “minding” machines. |

| Transportation: Moving materials around the factory. Buying raw materials and components from distant suppliers. |

| Extra processing: Processes that appear productive but are unimportant to the customer. Painting and finishing components that are not seen. Designing additional features into a product that the customers do not use e.g. many features in Excel. |

| Excess inventory: Having materials, components, work-in-process, and finished goods levels above the immediate need. |

| Waste of motion: Having to search for tools, parts, or forms. |

| Defects, scrap and rework in production: Complex inspection steps to overcome poor processes or poor design. |

| Unused employee creativity: Employee ideas having to hurdle many obstacles before adoption. |

“Most business process are 90% waste and 10% value-added work.” Dr Jeffrey Liker

Boeing reduced over a trillion internal transactions through adopting lean.

2. Adopt Toyota’s 14 principles

I believe Toyota to be possibly the greatest company in the world. It has 14 principles which are the backbone to its culture and Toyota can embed these principles in all countries it operates within. It’s Kentucky plant, in the USA, exceeded all Toyota expectations with its acceptance of the Toyota way. To understand the Toyota principles, one needs to read Jeffrey Liker’s book[i] The Toyota Way. He has broken them down into four categories as set out in Exhibit 2.

Exhibit 2: Toyota’s 14 management principles

| Philosophy | Principle 1: Base your management decisions on a long-term philosophy, even at the expense of short-term financial goals. |

| Process

(Eliminate waste) |

Principle 2: Create continuous process flow to bring problems to the surface. |

| Principle 3: Use “pull” systems to avoid overproduction. | |

| Principle 4: Level out the workload (Heijunka). | |

| Principle 5: Build a culture of stopping to fix problems, to get quality right the first time. | |

| Principle 6: Standardized tasks are the foundation for continuous improvement and employee empowerment. | |

| Principle 7: Use visual control so no problems are hidden. | |

| Principle 8: Use only reliable, thoroughly tested technology that serves your people and processes. | |

| People and Partners (Respect, Challenge, and Grow Them) | Principle 9: Grow leaders who thoroughly understand the work, live the philosophy, and teach it to others. |

| Principle 10: Develop exceptional people and teams who follow your company’s philosophy. | |

| Principle 11: Respect your extended network of partners and suppliers by challenging them and helping them improve. | |

| Problem solving (Continuous Improvement and Learning) | Principle 12: Go and see for yourself to thoroughly understand the situation (Genchi Genbutsu). |

| Principle 13: Make decisions slowly by consensus, thoroughly considering all options and then implement the decisions rapidly. | |

| Principle 14: Become a learning organisation through relentless reflection (Hansei) and continuous improvement (Kaizen). |

3. Build a culture of stopping to fix problems, to get quality right the first time

This is an important principle for the finance team to master. Finance teams invariably go from:

- One month-end to another without improvement

- One annual plan to another without improvement

- One year-end to another without improvement.

Whereas if we adopted this Toyota principle we would evaluate, after process has finished, and ask what we can do better next month, next year.

We would reduce the number of internal transactions, the number of spreadsheets and constantly review each processes’ timeline to further eliminate waste and shortened timelines.

4. Use visual control so no problems are hidden

Toyota is famous for its “andon cord” if problems occur. Andon refers to the pull cord where any worker on the production line can stop production, and ask for help, if they see a fault that cannot be fixed by them or the next workers before it will be covered up by a panel. Immediately lights flash and that part of the production line is halted. The workers below are unaffected as there is a feed in line with about eight minutes of product to work on. Trained engineers rush in and fix the problem. They have up to eight minutes before the whole production line will be halted. The ability of anyone to stop production and activate the flashing lights to get the roaming engineers to the spot quickly is a major advantage Toyota and other manufacturers have when using this visual control.

Visual control is an important principle for the finance team to master as many reports need a rocket scientist to read them. Whereas, if we adopted this Toyota principle we would make:

- All reports so clear that nobody needs to ask questions about them – I call it passing the 14-year-old test

- Use some sort of “and on cord” like a “red cone” so staff, within the accounting function, can signal that they are having a problem that might delay an accounting process, at month-end / annual planning/ annual accounts

- Use of staff notice boards, screens in canteens to report progress

5. Use Kanban Boards

Here we need to adopt visual control techniques which are part of the lean or agile movement. Creating a Kanban board to visually manage your work is a great way to increase your overall effectiveness and efficiency. Kanban is also a skilful way to instil a sense of accomplishment among a team. Let’s look at why this is the case.

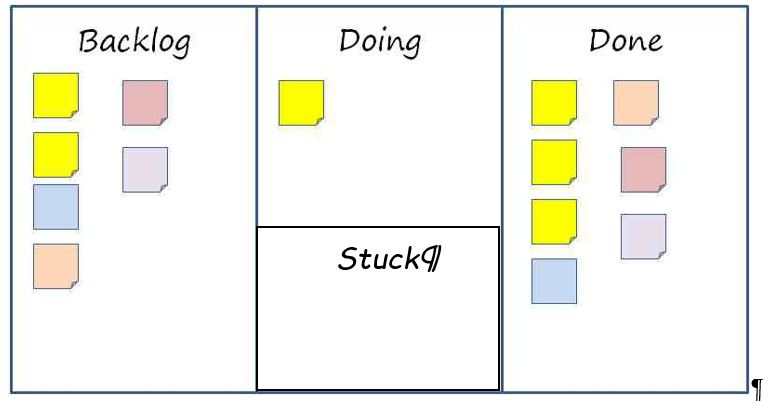

A Kanban board is a visual process and project management tool that helps teams organise and manage their work. Kanban boards allow teams to visualize their work and understand what is going on at a glance. By using note cards or sticky notes to represent work items, you can show any sized body of work such as a project (involving numerous tasks) or a task (usually involving only one person). Different colours are for different staff, or work groups. Lanes can be used to represent backlog, doing, or done as shown in Exhibit 3.

Exhibit 3: Kanban board used to help staff manage daily workflow

Kanban boards visually show the work in progress. This way, everyone is kept in the loop. It is particularly powerful when staff hold daily SCRUM meetings which are stand–up 15 minute meetings first thing each morning.

Kanban boards work well for any type of work. It’s so flexible that you can start with whatever process you already have. The Kanban method uses a pull system. Instead of trying to do 10 things at once, manage your personal tasks by “pulling” in new work only when you are finished with the current work.

Kanban boards show a team’s accomplishments. Have you ever had a hard time explaining to your boss what you’re working on because you have so many things on your to-do list that you don’t know where to begin? By showing him your Kanban, he will instantly see all your work and understand your workflow.

6. Use only reliable, thoroughly tested technology that serves your people and processes

Toyota are never the first to use a new technology. They let others break-in the new ground. They are, without doubt, the best users of a new technology once they have ascertained that it will serve their staff and their processes.

This has important ramifications for the finance team in the selection of a new G/L, a planning tool, and a new accounts payable system.

7. Go and see for yourself to thoroughly understand the situation

Toyota supervisors and managers are always expected to “walkabout” to see for themselves what is happening. They do not rely on written reports or meetings. The Finance team should do more walkabouts especially with:

- Setting up new “paperless processes” with key suppliers

- Reducing waste within operations

- Visiting best practice sites, around the world.

I firmly believe if CFOs visited more sites that are using their intended new applications they might think twice. I am referring to some of the large G/L applications that are so complex only rocket scientists can implement them, and the organisation and their bank account are now taken hostage for the foreseeable future.

8. Make decisions slowly by consensus, thoroughly considering all options and then implement the decisions rapidly

Toyota is very slow in the planning stage but very fast in the implementation and commissioning. This is because everything, I mean everything, has been discussed and contingency plans agreed, ready for action if required. The Finance team should take heed of this principle especially with the:

- Changing of the general ledger

- Purchasing a planning tool

- Migration from annual planning to quarterly rolling forecasting

9. Become a learning organisation through relentless reflection and continuous improvement

One thing that sets Toyota apart from nearly all organisations is its continuous improvement. Every employee is expected to reflect each day “What could I do better tomorrow?” and come up with at least one innovation per month, no matter how small. The Toyota average, internationally, is 10 innovations per employee per year.

All the great paradigm shifters such as Peter Drucker, Jim Collins, Peters and Waterman have preached the need to innovate and not spend too much time trying to second guess whether it will work or not.

All the built to last companies came up with their big ideas through a bit of serendipity. Jim Collins refers to it as very much like Darwin’s survival of the fittest. Try a lot of things and only let the strong ideas survive. In the Motorola example he points out that Motorola see innovation very much like a growing tree, you let it branch out, but you are also constantly pruning.

10. The 5s technique from Gemba Kaizen

Far too often teams will perpetuate and support systems and processes that have been broken for some time. Kaizen, which stands for change is good, is saying to us that “The past methods are not the way of the future”.

Steve Jobs believed that few in management thought deeply about why things were done. He came up with this quote I want to share with you. I believe this quote should be on every wall and in front of every work station in the finance team work area.

“Your time is limited, so don’t waste it living someone else’s life. Don’t be trapped into living with the results of other people’s thinking. Don’t let the noise of other’s opinions drown your own inner voice.” Steve Jobs

The father of Kaizen could be said to be Masaaki Imai who wrote the best selling book “Kaizen” and the “Gemba Kaizen” [ii]. He is quoted as saying

The 5S’s were developed originally through intensive trial and error in a manufacturing context. The idea being that work is triggered by a customer and from that point conditions and standard procedures will typically:

- Complicate the work unnecessarily

- Impede progress towards satisfying the customer

Sort

The first thing we need to do is sort out all items at the work place between those that are necessary and unnecessary. Here we now adopt Peter Drucker’s abandonment

Drucker, who I consider to be the Leonardo de Vinci of management, said, “Don’t tell me what you’re doing, tell me what you’ve stopped doing.” He frequently said that abandonment is the key to innovation. I consider this advice to be in the top ten tips he gave us. The advice he passed on is really quite profound.

“If leaders are unable to abandon yesterday, they simply will not be able to create tomorrow”

“Without systematic and purposeful abandonment, an organization will be overtaken by events. It will squander its best resources on things it should never have been doing or should no longer do. As a result, it will lack the resources needed to exploit the opportunities that arise”

In the world of commerce this trait is equally damaging. We will hold on to systems, keep going with projects, keep writing that report that nobody reads because to remove it would mean a loss of face. Let’s get over it.

As part of this exercise it is common for a team, independent of those working in the area to go around with red tags, placing them on items that they do not think are necessary. Staff in the next few weeks then, as they use the item, are aware whether it is necessary or not and argue the case.

At the end of this process management remove all the red tagged items and then investigate how this surplus happened to prevent its reoccurrence.

Straighten

Once the unnecessary items are removed you classify the remaining items by use and arrange them accordingly to minimise search time and effort. Everything should have its place. I remember going into a workshop where a stencil had been drawn on the wall to indicate where the tool was meant to be stored.

In a factory setting even hallways are clearly marked so that no storage is ever allowed in them.

How many times, when cleaning your car or tidying your file explorer, do have that Aha! moment?

Scrub

When hand washing your car, you are naturally close to it and notice a nail in the tyre, a loose piece of bodywork, a scratch on the paintwork. This process often finds issues that will become bigger problems later.

In an office and plant situation often, safety issues can be unearthed and potential fire hazards rectified.

Systemize

This is where we sort, straighten and scrub on a systematic basis. Thus, ensuring that there is no lapse in the timeframe. As Masaaki Imai says, “To do Kaizen once is easy, to keep doing Kaizen continuously, day in, day out, is an entirely different manner”.

Self-discipline

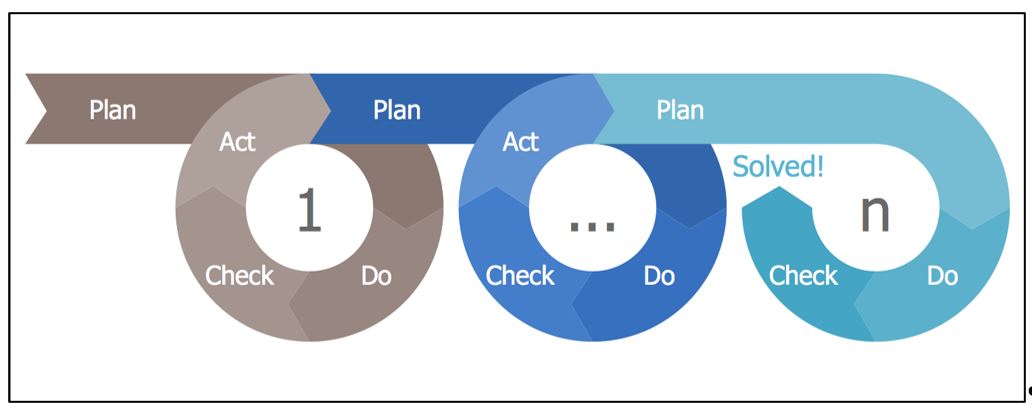

When the new approach has been worked out, it needs to be followed by all and that is where self-discipline comes to the afore. In addition, the continuous nature of planning a new level of performance, doing the new procedures, checking progress and acting on the feedback means that the PDCA process is continuous, see Exhibit 4.

Exhibit 4: The multiple loops of the Plan Do Check Act technique

11. Jim Collins’ five step innovation technique

All the great paradigm shifters, such as Peter Drucker, Jim Collins, Peters and Waterman have preached the need to innovate and not spend too much time trying to second guess whether an innovation will work or not. Peters and Waterman advised that you get your team to see innovation.

Jim Collins has created a blue print for evolutionary progress based on analysing 3M. The five steps are:

- Give it a try and make it quick.– Don’t sit, vary, change, solve the problem, seize the opportunity, experiment, and try something new even if you can’t predict precisely how things will turn out.

- Accept that mistakes will be made. Since you can’t tell ahead of time, which variations will prove to be favourable, you have to accept failures as an evolutionary process.

- Take small steps. It’s easier to tolerate failed experiments when they are just that, experiments, not massive corporate failures.

- Give people the room they need. When you give people a lot of room to act you can’t predict precisely what they will do, and this can be beneficial. 3M give their staff 15% of discretionary time to play around with ideas. The “Post It” note was developed this way.

- Build a ticking clock. 3M ideology creates an environment where innovation is cut loose and lights a hot fire under the “innovation” pot and stirs vigorously.

12. Use the five whys rule to get to the heart of the problem

Six sigma and Toyota have adopted “The five whys” to get to the root cause of a problem. It is like peeling the layers off an onion. To each answer to a why question you then ask, “Why is that?” The rule states that by the fifth why you will have located the real problem, and if rectified, a permanent benefit will flow back to the organisation.

13. Post-it re-engineering of inefficient routines

Re-engineering can be a complex or a relatively easy exercise—the choice is yours. Many organisations start off by bringing in consultants to process map the existing procedures. This is a futile exercise; why spend a lot of money documenting a process you are about to radically alter and when it is done only the consultants will understand the resulting data-flow diagrams?

Next steps:

Purchase David Parmenter’s mini toolkit ’10+ Techniques to adopt from the lean movement ‘ (article +E-Templates) that can be source from this link.

Writer’s biography

David Parmenter is a speaker on and author of “The Leading-Edge Manager’s Guide to Success”, “Key Performance Indicators” (Wiley).

Contact at: parmenter@waymark.co.nz, www.DavidParmenter.Com.

[i] Jeffrey Liker, The Toyota Way: 14 Management Principles from the World’s Greatest Manufacturer (New York: McGraw-Hill, 2003).

[ii] Masaaki Imai, Gemba Kaizen: A Common-sense Approach to a Continuous Improvement Strategy, Second Edition (McGraw-Hill Education; 2 edition, 2012)